Advanced Protection for Steel Pipes: Lining and Coating Solutions

BCS Steel Pipe offers a wide range of internal and external coating solutions for steel pipes designed to protect against corrosion, mechanical damage, and other environmental factors. While steel is a durable and long-lasting material, the lifespan of uncoated steel can significantly decrease—from 50 years to just 10-15 years—if the coating process is not meticulously applied, free from air bubbles, and properly executed. To combat this, we provide advanced coating options to ensure the longevity and reliability of our pipes.

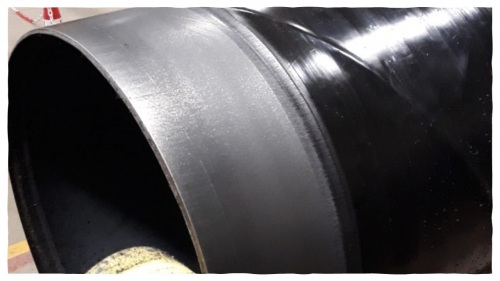

Our External Coating options include 3LPE/3LPP, a multilayer system consisting of a high-performance anticorrosion fusion-bonded epoxy (FBE) as the first layer, followed by a copolymer PE/PP adhesive layer for enhanced adhesion, and a final outer layer of polyethylene/polypropylene for mechanical protection. For Internal/External Coating, we also use epoxy paints, which are highly effective in protecting both the inside and outside surfaces of pipes from corrosion. This type of coating is commonly used in applications like potable water, wastewater, petroleum, and gas pipelines, ensuring durability and long-term performance across a wide variety of industries.

EXTERNAL COATING STANDARDS

SURFACE PREPARATION : ISO 8501 – 1, ISO 8501 – 2, ISO 8501 – 3

POLYETHYLENE COATING : DIN 30670

POLYPROPYLENE COATING : DIN 30678, NFA 49711

EPOXY COATING : EN 10289, AWWA C210, NFA 49709

FUSION BONDED EPOXY : AWWA C213

INTERNAL COATING STANDARDS (LINING)

SURFACE PREPARATION : ISO 8501 – 1, ISO 8501 – 2, ISO 8501 – 3

EPOXY LINING : EN 10289, AWWA C210, NFA 49709,

FUSION BONDED EPOXY : AWWA C213